With a DWT = steam-fluidized bed drying (fluidized bed drying with superheated steam as fluidization medium), the carbon moisture before gasification can be efficiently reduced to 5-15%.

Advantages of the process

- High efficiency, low area requirement

- Cost-effective low-pressure steam can be used as a heat source

- Coal moisture is recovered from the process and can be used as a heating medium for the process by mechanical exhaust vapour compression

- Further usage options are:

- Heat dissipation to another heat sink (e.g. heat pump, feed water) or

- use via an expansion turbine

- High dust separation efficiency, emissions are explicit below the ecological limit

- Safe operating status (inert steam atmosphere) due to closed steam circuit under slight overpressure in the dryer

History of DWT and references

In the 1980s and 1990s, the development of the technological basis for a process of low-temperature steam fluidized bed drying of coal and sludge began by UET Freiberg, a predecessor of CHOREN Industries.

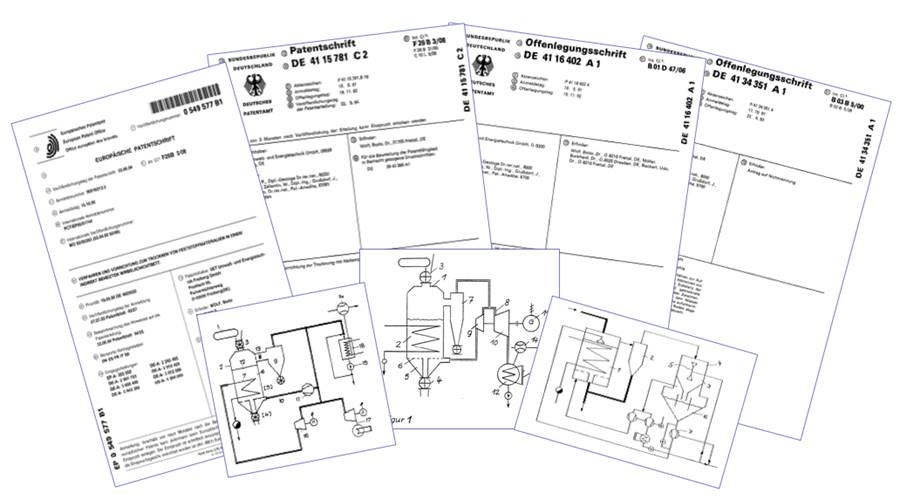

- 1990s: Application for several patents and installation of various DWT sludge drying plants (UET)

- 1991 Design for a 55 t/h DWT carbon drying plant for China

- Studies on scale-up to 100 t/h

- 2010 Conception of strategic partnerships with DWT by CHOREN Industries